Unlocking Innovation in Metal Fabrication: The Power of the Rapid Prototyper

In today's fast-paced manufacturing environment, the ability to rapidly develop, test, and refine product prototypes is a critical factor for success. At the forefront of this technological revolution is the rapid prototyper, a groundbreaking tool transforming the way metal fabricators and engineering teams operate. This article delves into the profound impact of the rapid prototyper within the metal fabrication industry, highlighting how it accelerates innovation, improves quality, and reduces costs.

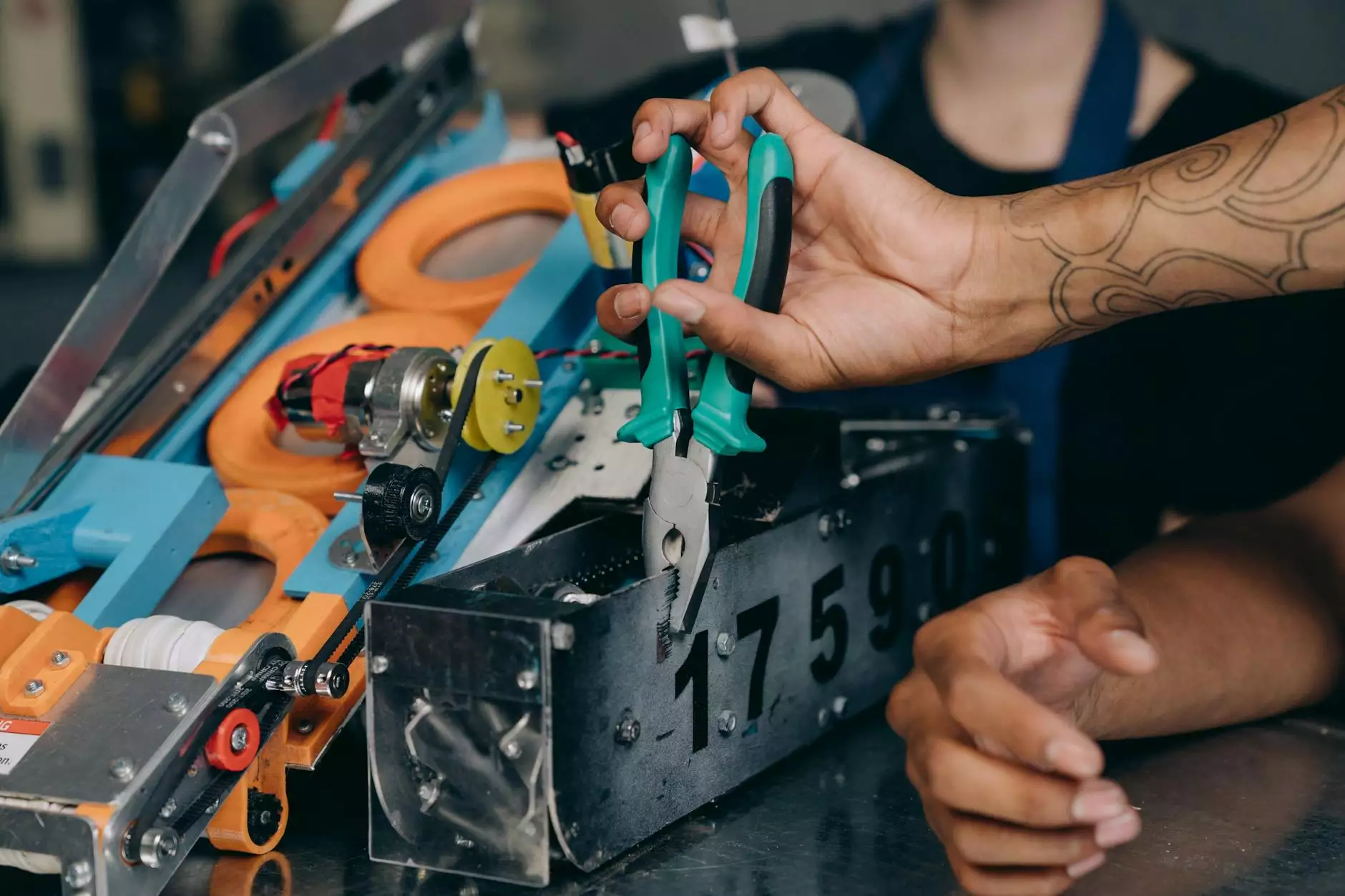

Understanding the Role of the Rapid Prototyper in Modern Metal Fabrication

The rapid prototyper refers to advanced manufacturing technology that enables the swift creation of functional prototypes or small batch production parts, particularly from metal materials. Unlike traditional manufacturing methods that often involve lengthy processes, these machines leverage additive and subtractive techniques to produce complex geometries with unparalleled speed and precision.

Key Technologies Behind the Rapid Prototyper

- Selective Laser Melting (SLM): A type of metal 3D printing that fuses metal powder layer-by-layer using a laser beam, allowing for intricate and durable prototypes.

- Direct Metal Laser Sintering (DMLS): Similar to SLM, DMLS produces high-strength parts suitable for functional testing and end-use applications.

- Computer Numerical Control (CNC) Machining: High-precision subtractive manufacturing that rapidly produces prototypes with tight tolerances from various metals.

- Hybrid Approaches: Combining additive and subtractive methods for optimizing speed, detail, and material properties.

Benefits of Incorporating the Rapid Prototyper in Metal Fabrication

Implementing the rapid prototyper in a metal fabrication business, such as deepmould.net, offers numerous strategic advantages that can redefine product development cycles and overall competitiveness.

1. Significantly Accelerates Product Development Cycles

The traditional route from concept to physical model can take weeks or months, involving multiple fabrication stages, tooling, and assembly. The rapid prototyper reduces this timeframe to days or even hours, allowing engineers and designers to iterate quickly. This rapid feedback loop facilitates faster refinement, leading to better products in a shorter span.

2. Enhances Design Flexibility and Creativity

With rapid prototyping technology, complex geometries, internal channels, and organic shapes that are difficult or impossible to produce with conventional methods become feasible. This opens up new realms of design innovation, enabling engineers to experiment with novel features and optimize performance without being constrained by manufacturing limitations.

3. Reduces Costs and Waste

Traditional manufacturing often involves expensive tooling and extensive material waste. The rapid prototyper minimizes both by allowing for low-volume production and in-situ modifications. This cost-effective approach is especially beneficial for small batch productions, testing, and customization projects, ultimately improving profit margins.

4. Improves Product Quality and Functionality

Prototypes created using advanced rapid prototyper technologies are highly functional and accurate, providing a reliable basis for real-world testing. This means errors can be detected early, and adjustments can be made before committing to mass production, reducing the risk of costly recalls or redesigns later.

5. Facilitates Better Collaboration and Communication

Physical prototypes help bridge the gap between design teams, engineers, clients, and stakeholders. Having tangible models accelerates understanding, feedback, and decision-making processes, fostering a collaborative environment that drives innovation forward.

The Strategic Advantage of Rapid Prototyping for Metal Fabricators Like Deepmould.net

For companies specializing in metal fabrication such as deepmould.net, integrating the rapid prototyper into their workflow means staying ahead of competitors by offering faster turnaround times, higher-quality prototypes, and more customized solutions. This strategic advantage can open new markets and reinforce customer satisfaction.

Why Deepmould.net Embraces Advanced Prototyping Technologies

Deepmould.net recognizes that innovation is key to growth. By investing in state-of-the-art rapid prototyper machinery, they significantly cut down development cycles. The result is a more agile, responsive manufacturing process capable of tackling complex projects with precision and efficiency. Their commitment to quality, innovation, and customer satisfaction positions them as leaders in the metal fabrication industry.

How to Maximize the Potential of the Rapid Prototyper in Metal Fabrication

For organizations looking to leverage this technology effectively, several best practices and considerations can ensure maximum impact:

- Choose the Right Technology: Select the most suitable rapid prototyper based on material compatibility, part size, and desired mechanical properties.

- Design for Additive Manufacturing: Optimize CAD models for manufacturability, including reducing complexity and ensuring proper support structures.

- Material Selection: Utilize high-quality metal powders and alloys tailored for specific applications, such as aerospace, automotive, or medical devices.

- Iterative Testing: Use rapid prototypes for extensive testing to verify components' functionality before full-scale production.

- Collaborate Across Teams: Foster collaboration between design, engineering, and manufacturing teams to streamline the prototyping process and implement improvements swiftly.

The Future of Metal Fabrication with Rapid Prototyping

The landscape of metal fabrication is rapidly evolving, driven by breakthroughs in digital manufacturing and rapid prototyper technologies. Predictions for the next decade include:

- Increased adoption of additive manufacturing, allowing for even more complex and lightweight structures.

- Integration of IoT and AI to enable smart monitoring and adaptive manufacturing processes.

- Greater customization and personalization in product design, facilitated by flexible prototyping systems.

- Sustainable manufacturing practices emphasizing material efficiency and reduced carbon footprint through precise, small-batch production.

Conclusion: Embracing the Power of the Rapid Prototyper for a Competitive Edge

In summary, the rapid prototyper is a pivotal technology that empowers metal fabricators like deepmould.net to accelerate innovation, improve product quality, and reduce costs. As industries continue to demand faster, more complex, and highly customized solutions, integrating advanced prototyping systems will not just be a strategic advantage but a necessity for staying ahead in the competitive landscape.

Whether you're developing new machinery parts, medical implants, aerospace components, or consumer products, the ability to rapidly turn ideas into tangible, functional prototypes can revolutionize your business model. Embrace the future of metal fabrication with the power of the rapid prototyper and unlock limitless possibilities for growth and innovation.